Tuesday, December 14, 2010

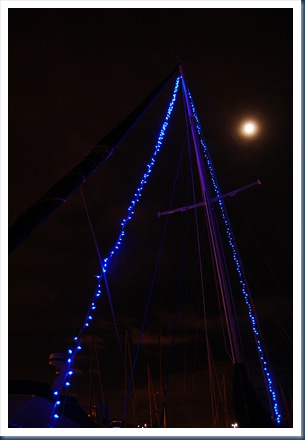

Festive

Tuesday, November 30, 2010

It’s beginning to look a lot like Christmas

We’ve even hung our stockings by the chimney with care.

Wednesday, November 24, 2010

Sail Repair Seminar

The five of us sit quietly on little wooden benches in our socks and slippers. Our eyes are trained intently on our laps, needles in hand, as we carefully pull stitch after stitch through a piece of sail cloth. We’ve just learned the technique for hand-sewing a brass ring onto a sail, and while our rings certainly don’t look as lovely as our instructor’s do—we have a bit of that unsightly

“pinwheeling” going on—we’re feeling pretty satisfied with ourselves.

A few times each year, Carol Hasse, along with her crew at Port Townsend Sails, opens the loft to 10 students for a weekend-long seminar on inspecting and repairing sails. Last weekend, I was lucky enough to attend.

One of the aspects of the cruising/living aboard lifestyle that I’ve always found appealing is that of self-sufficiency. Whether you sail offshore or just off the breakwater, being able to maintain your vessel and all its systems brings a measure of satisfaction, security and independence.

And since sails are arguably the most important system on a sailboat, I figured it was time I learned something about how to keep them in shape, how to make repairs and how not to freak out when a sail tears or a slide rips out or we lose a hank (as is bound to happen).

I showed up at 8:30 AM on Saturday morning not sure what to expect. After introductions, we broke up into two groups of five and jumped right in. My group headed off to the hand-working room where we got busy sewing brass rings, hanks, slides and easy reefs onto our sail “sampler.”

Halfway through the day, we moved over to the main loft area for a lecture followed by a hands-on inspection of our sails (each student was encouraged to bring in a sail to inspect). As I headed up the street to my hotel that night, my head was spinning! We’d crammed so much into one 9-hour day, and I was feeling slightly overwhelmed. But after a good night’s sleep and a couple cups of coffee the next morning, we were back at it—and it felt great.

My slipper-clad group of five started out Day Two on the sewing machines. We added a leech table, poked holes in our sail—and then fixed them in various ways (with Dacron tape or with a “TV Screen Patch”). We added chafe protection like spreader patches and wings, and I must say, I was having fun. I’ve done a bit of sewing in the past (fleece coats for Greta and a Santa suit for my brother and sister-in-law’s dog, George), but even Scott who hadn’t touched a sewing machine before picked it right up. I even had Aaron add a Sailrite machine to his Craigslist search (since I haven’t been a good enough girl this year for Santa to shell out $900 for a new one).

We found ourselves back in the hand-working room after lunch for another round of needle work, this time sewing on a leather chafe guard and learning a number of different stitches that would come in handy when the boat is tossing around and you can’t go below to use your machine (or if you’re like me and don’t have one).

With my certificate in hand at the end of the day, I truly felt a sense of accomplishment. The skills I learned in the seminar gave me the confidence I need to feel comfortable addressing the needs of our sail suit—from inspection to preventative care to emergency repairs. Aaron and I have taken a number of classes over the past year or so, and the feeling of empowerment that comes along with knowledge is something that I never get tired of.

A few examples of what we learned:

For more information: Port Townsend Sails – Sail Repair Seminars

Monday, November 22, 2010

Brrrrr!

It’s getting pretty chilly!

Definitely the kind of day that makes us want to sail off into the tropics…

We took a short walk around the marina, then came back and tried to throw snowballs into the cockpit of s/v Hello World across the water from us.

Thursday, November 4, 2010

Cookie Recipe

Severed Finger Cookies

1 cup butter, softened

1 cup powdered sugar

1 egg

1 teaspoon almond extract

1 teaspoon pure vanilla

2 ¾ cups flour

1 teaspoon baking powder

½ teaspoon salt

Slivered almonds (for bones)

Sliced almonds (for nails)

Red icing gel (for blood)

In large bowl, add butter and sift in powdered sugar; beat well. Beat in egg, almond extract and vanilla. Sift in flour, baking powder and salt, mixing to combine (dough will be a little crumbly). Cover and refrigerate for at least 30 minutes until well chilled (I pat the dough into a disk and wrap in plastic wrap.)

Preheat oven to 325°. Working in small batches and keeping the remaining dough in the refrigerator, roll heaping teaspoonfuls of dough into a finger shape. Smaller is better here, since they puff slightly while baking. Work quickly to form the knuckles. Then use a toothpick to create the wrinkles in the knuckles and add texture to the “severed” end. Press an almond slice firmly into the nail area and stick a slivered almond into the other end.

Once filled, I like to chill the cookie sheet again before baking.

Bake for 20–25 minutes. Let cool on cookie sheet for 3 minutes before transferring to a cooling rack. Immediately remove the nail, squeeze a dollop of red icing gel underneath and replace. Add small amounts of red icing gel to the “severed” end.

Monday, November 1, 2010

Keeping the water out

We’ve had a leak since we got the boat that we were finally able to fix with some helpful insight from another HC33 owner. Thanks Steve! The leak was coming from the hole in the deck where our diesel heater’s stove pipe passes through the deck.

To fix it, the first thing I did was remove the charlie noble (boat chimney) to get at the hole.

Next was to remove the fairing block – it was cracked in half so I used epoxy to glue it back together. For this project I used West System G/Flex due to its greater elasticity.

We could see right where the water was coming in.

With the fairing block removed I used a Dremel with a sanding cylinder bit to clean out the old sealant and prepare the surface for some epoxy and fiberglass tape.

Then I applied the epoxy and fiberglass tape.

I let that cure overnight and then cut off the excess with the Dremel and a cutoff wheel. ALL HAIL THE DREMEL! I also sealed up the holes in the deck where the fairing is screwed down.

Then I taped off the area in preparation for applying the sealant.

I reattached the newly fixed-up fairing pad and tightened the screws just enough to that the sealant was squishing out. Then wiped away the excess. (With sealants you want to wait until it’s cured before you screw down the item tightly.)

I pulled the tape while the sealant was still wet.

I let that cure overnight, then tightened up the screws.

Next was to repeat the tape and sealant process with the charlie noble.

So after we got everything put back together all we had to do was wait for it to rain. We didn’t have to wait long. Fortunately the work paid off and the leak is fixed.

Saturday, October 30, 2010

Halloween on Bella Star

Seeing how we’re fans of all things pumpkin this time of year (and all things in the ice cream/gelato family year round), we recently tried the pumpkin gelato from Ballard’s D’Ambrosio Gelato. One night this summer while enjoying a deliciously creamy cup with our friends, Jen & Harley, we bumped into the owner outside. We got to chatting, and I offered up a suggestion for the fall menu: pumpkin spice. And he scoffed! Literally scoffed. And with his Italian accent told me, quite directly, “In Italy, we do not do spice.” Well, okay… You can imagine my surprise, then, to find him advertising pumpkin (with spice) as a new fall flavor. Pretty sure I deserve a cut. Or at least a free pint.

This year’s pumpkin carving started out innocently enough…

Have a spooktacular Halloween!

Saturday, October 23, 2010

Mast is vertical

We were able to finish up our work and get the mast stepped today.

We replaced the spreader lights and wiring. We also cleaned up some corrosion on the spreaders where the old lights were mounted.

Tada!

Removing the mast and stepping it again was a very smooth process. The guys at the Seaview West yard do a nice job.

We were going to replace the good luck coin at the mast shoe, but decided to leave the old one in there. Seems like it’s been working pretty well.

We feel like we’ve turned a corner here since we’re starting to put stuff back together instead of taking it apart. Our new sails will be ready pretty soon and we’re REALLY looking forward to getting away for a weekend, so we’re focusing on getting the boat back to sailable condition.

Tuesday, October 19, 2010

Living Aboard Series

The great folks over at Three Sheets Northwest, our local online boating magazine, are profiling a series of liveaboard families this week. Start with Liveaboards: who are they, and why do they do it? to get some interesting insights into the lifestyle. If you’ve been following our blog for awhile, you’ll remember Al from our post about his Christmas spirit—he put us all to shame by hoisting a lighted Christmas tree to the top of his mast last year. Just wait until this year, Al! :)

Saturday, October 16, 2010

Mast work ongoing

Had a smidge of corrosion underneath the boom vang plate.

Took the Dremel wire wheel to it and got to shiny metal.

Epoxy paint being applied:

The whole mast could use a paint job, but we’re on a tight schedule here.

Did the top while we were was at it.

Nicole prepped it up.

Nice an pretty for any aircraft flying overhead.

And this thing?

It’s shot. Electrical connections inside are corroded and broken. A replacement is pretty expensive. Stay tuned – we going to try to make our own!

Monday, October 11, 2010

And the Thunder Rolls

“At least we picked a good time to be mast-less.”

The peal of thunder that rolled through Ballard last night woke us from our cozy slumber with the loudest C-R-A-C-K I’ve ever heard. My heart was thumping, as I waited for the next burst. But instead, I burst out laughing—at Aaron’s quip about us picking a good time to be without our lightning rod of a mast.

Looks like lightning struck the Ballard Locks (instead of someone here at the marina), knocking out power to the large locks.

http://www.myballard.com/2010/10/11/ballard-locks-hit-by-lightning/

Sunday, October 10, 2010

Powerboat Mode

We pulled the mast this weekend in order to run the cable for the new anemometer, replace some bad wiring to the spreader lights, and install a couple new halyards. Also the lens on the steaming/anchor light combo is practically opaque. The good news is, at least for a week or two, I won’t have to be scurrying around on deck in my underwear at 3am securing noisy halyards.

The bad news is that getting wires where we want them in the mast is turning out to be fairly difficult.

We have always been annoyed by the sound of wires slapping around inside that mast when rolling at anchor. One of our primary objectives was to fix this.

We got all the wire run from the masthead, but now we’re having trouble with the wires for the spreader lights. It’ll have to wait until next weekend to figure out.

Sunday, September 19, 2010

Bank 1 is toast

Ever since we put the boat back in the water after the haulout we’ve had some leaking at the stuffing box. (This is where the prop shaft passes through the hull.)

The only way we could address this is to open an access panel above it. The access panel is in the lazarette, under a bank of batteries of course.

In preparing to get in there, We found that all 4 of the batteries in that bank have ginourmous cracks in the top of the case. Likely due to some questionable charging practices on my part. Bank 2 is still in good shape, but they’re really old batteries so we’re going to replace all 8 of them.

So after some battery box destruction and considerable effort (they’re 77 pounds a piece) we got the batteries out.

The good news is that access to the stuffing box was excellent, and we were able to fix the leak. We just tightened it up slightly and then we motored around for awhile and verified that it was operating correctly.

Thursday, September 9, 2010

On the right track

Basically, the new track just slides into the old track.

I hoisted Nicole up a few times, first to clean the old track and then to give it a light lubrication. She’s a pretty good little mast monkey and is pretty comfortable with working aloft. Which kind of surprised me, since I copied the commercially available mast climbing setups by getting a used caving harness and line ascenders off eBay.

The track ships in a big box. This is as sharp a bend as it can take, so we had to remove the boom in order to install.

The existing track feeder also had to be enlarged to accept the new track. I’m not sure what people did before the Dremel tool was invented!

Ready for the new main! Should be ready in October.

![IMG_6779[1] IMG_6779[1]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgzW1P4qNcETwRg9I2akW-anzlQmK3gMhzQzt9RCi5VVo-WH7KVjU3a_lfB4ovO6lJZFfynRMYNnCWHE5JBsLpkus2MH5jV5FTzGpekZ3b2-_OPpEWPqJ-X1RDnfg95KnaOIGrgiup6pkEi/?imgmax=800)